3D Printed gear destroyer - in progress!

Hey all!

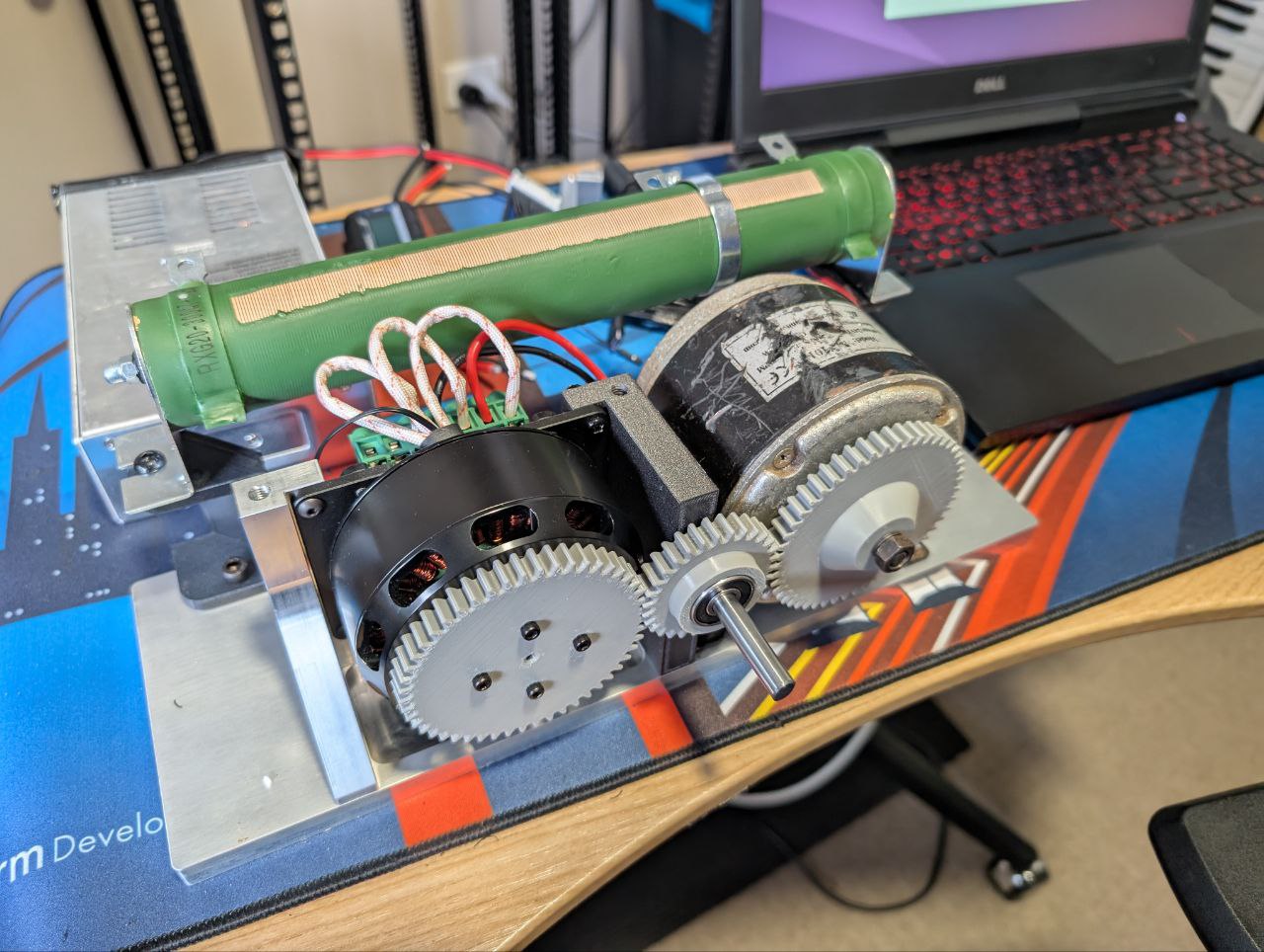

Several years back I made a video testing the strength of 3D printed gears - but that test was done using a static load and rightfully critiqued as an unrealistic representation of how the gears would wear in actual use. I've been working hard since to develop a method of testing 3D printed gears in a repeatable way, and I'm almost ready with the machine above.

This test setup uses a large brushless motor running off an O drive for precise rotational speed and torque - driving a DC motor which is being used as a generator to provide load. The power is burnt off as heat by the huge variable resistor above, and I'm hoping I can use it to figure out how all kinds of printed gears behave. I'm not great with code, and have been struggling with programming the O drive unit, but once that's resolved I should be able to start breaking some gears!

If there's any kind of test you'd like to see performed, let me know below! I'll start with materials, but could easily branch out to print settings, tooth profile or more. It should be fun :)

Thanks for being a part of the Maker's Muse community!

Angus ~ Maker's Muse

I’m looking forward to your findings on different materials. Wear rate and resistance on different loads and speeds…

I’d be applying them to clock gears - a different purpose than, for instance, combat robots ☺️

Nice! Clock gears should have less wear, but the backlash will be much more important.